At E4D Technologies, we know that a company with a healthy organizational culture will outperform a company with an unhealthy culture. Many companies are smart, but many struggle with delivering timely results with minimal interpersonal drama and disorganization. Patrick Lencioni defines a healthy organization as one that “has minimal politics and confusion, a high degree of morale and productivity and a very low turnover among good employees” (The Advantage, Pg 5). Our smart and healthy organization has successfully competed with much larger organizations and withstood the test. While many of those larger organizations have a brilliant and skilled workforce, we have the advantage of having the strength of a healthy organization to complement our smaller but equally skilled team. As a company that has focused on organizational health and creating a culture where people want to come and work, more than two-thirds of our team has been with us for more than five years; and half of that has been around for more than ten years.

Our culture enables us to innovate technology every day while genuinely enjoying the work that we do and the people who work with us. It helps us succeed in creative development, problem-solving and a variety of essential components of our business. We know every company has a culture, but not all companies intentionally develop a culture that promotes their purpose and values while looking to bring their customers the best value.

Here’s how our company culture contributes to our success in contract design and product manufacturing:

We Like to Say E4D Means Employees 4 a Difference

We understand that progress in the technology industry encompasses more than producing a great product. Not only does E4D make a difference for our customers around the globe with innovative products, but we also bring value to our local communities. We want our company values and ideas to go beyond the walls at E4D Technologies and positively affect people outside of our organization. For example, we make a difference in our community of Richardson, Texas, by uniting our employees in our company-wide volunteer program. We are blessed to be part of a great community that is a vital part of our employees’ lives.

We exist to enable individuals, teams, and companies to have the freedom to move forward. Our team places a heavy emphasis on creating opportunities for our employees to help our neighbors achieve their freedom to move forward. Serving our communities also has the added benefit of building stronger, long-lasting relationships with our employees, which are strengthened as we work to serve the community together.

Leaving Our Egos at the Door

As the cliche goes, “cash is king.” But the reason to be in business is to use that cash to create value. Our team strives to create an environment for the benefit of our customers, employees, end-users, investors, and communities based on mutual improvement, growth, and overall service. Contrary to most beliefs about business, profit is not our only purpose but a direct result of our aim.

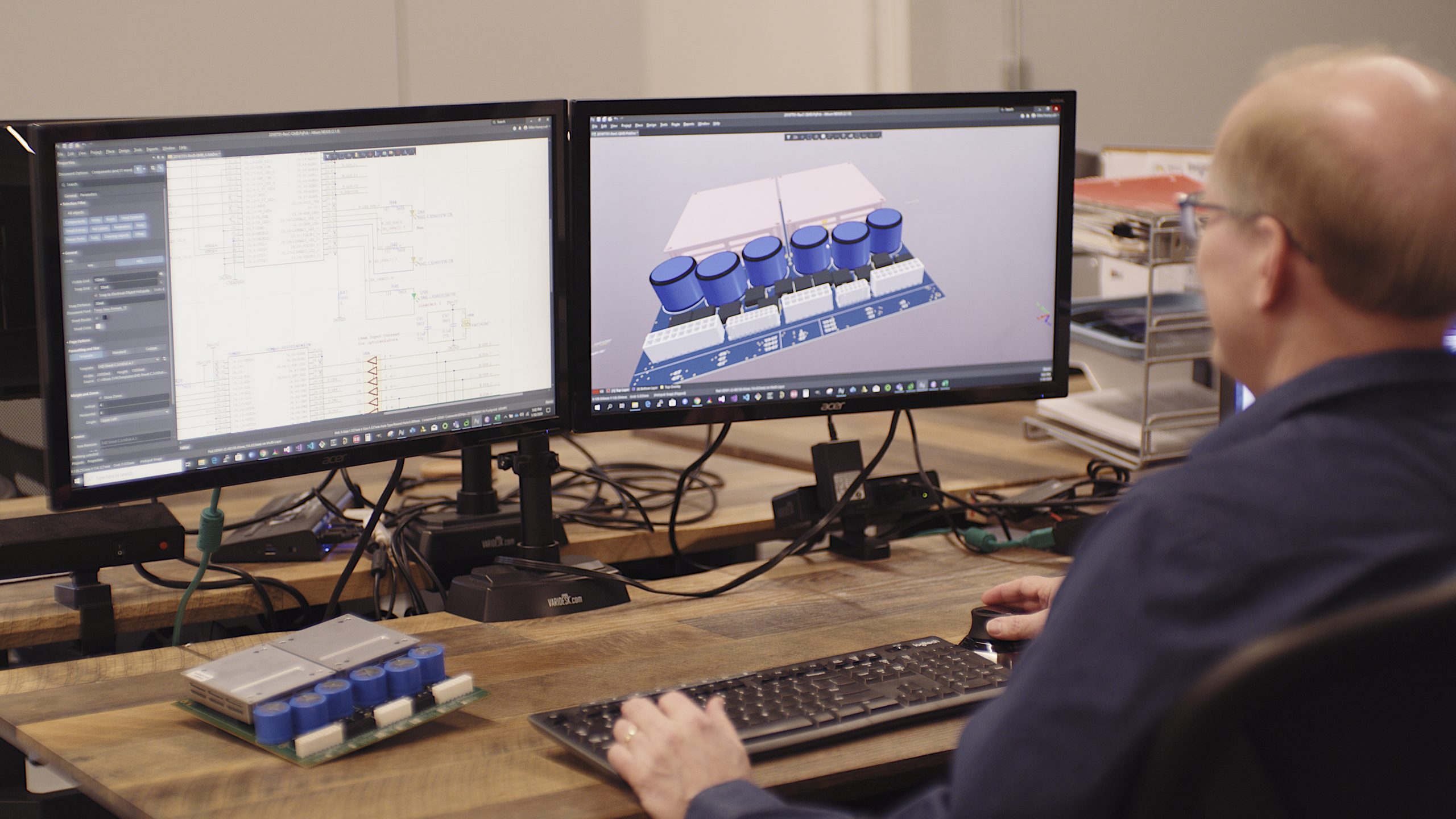

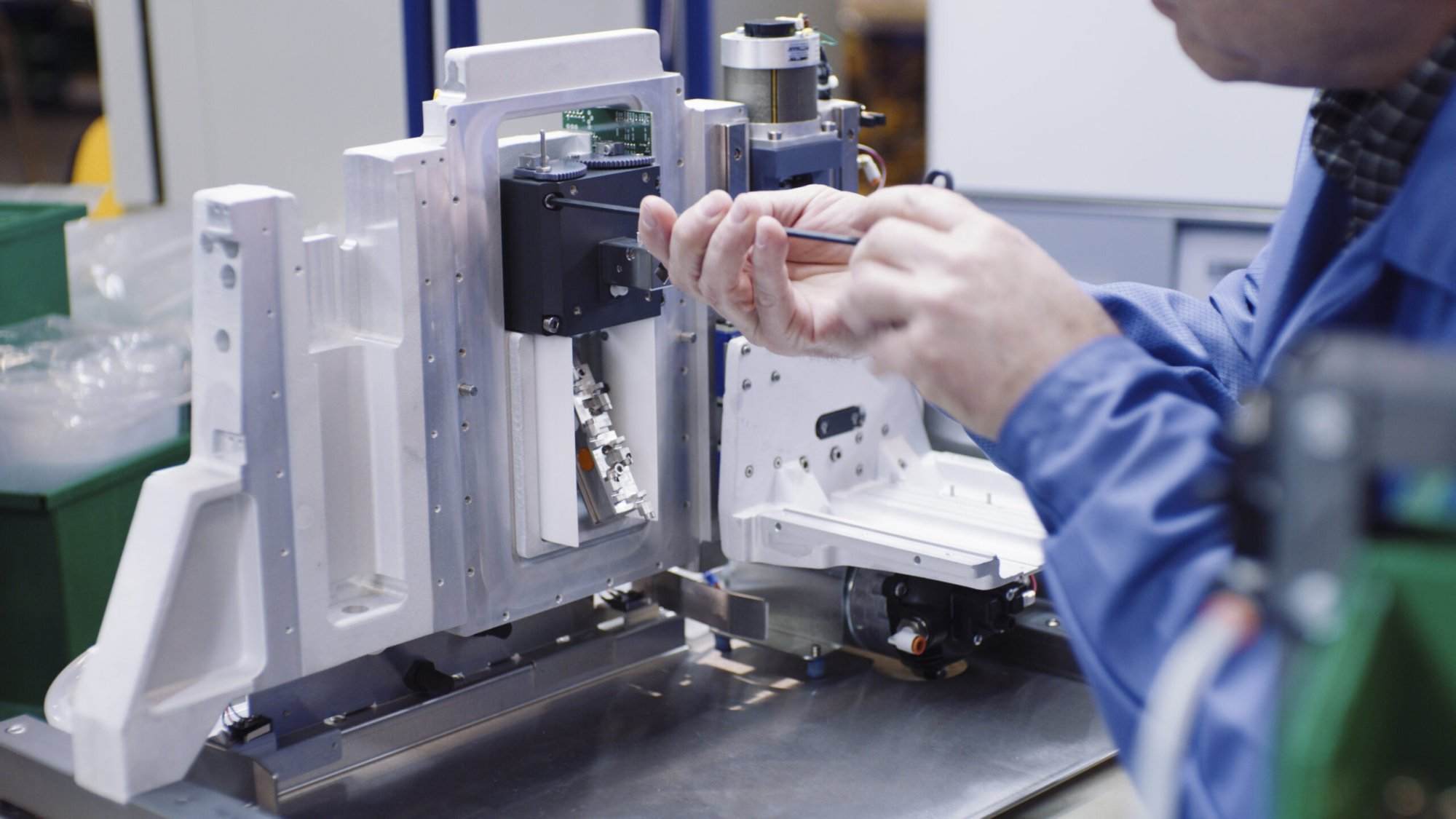

One of our core values is that we “leave our egos at the door.” This means that we acknowledge that it takes the whole team, regardless of title or role, to bring the best value to our customers and our employees. We value the diversity of experience, education and culture of our team. We recognize that we all have something important to contribute to each other, to our customers and to our community. Together, our team of experts has nearly 600 years of combined experience in all major engineering disciplines, and our team represents more than ten different countries. Under one roof, we work together to make complex technologies simple and bring our customers’ products to life. Through leveraging our diverse skills, cultures and experience, we provide everyone with the freedom to move forward.

This mindset and value breaks down silos and politics that can impact an organization’s health and deter the company from moving efficiently and effectively to what brings the most value. Our company culture brings our entire staff together with one motivating goal of moving forward. We want to make a difference in the future of design and manufacturing, and we’re working towards this goal every day.

Aversion to the Status Quo

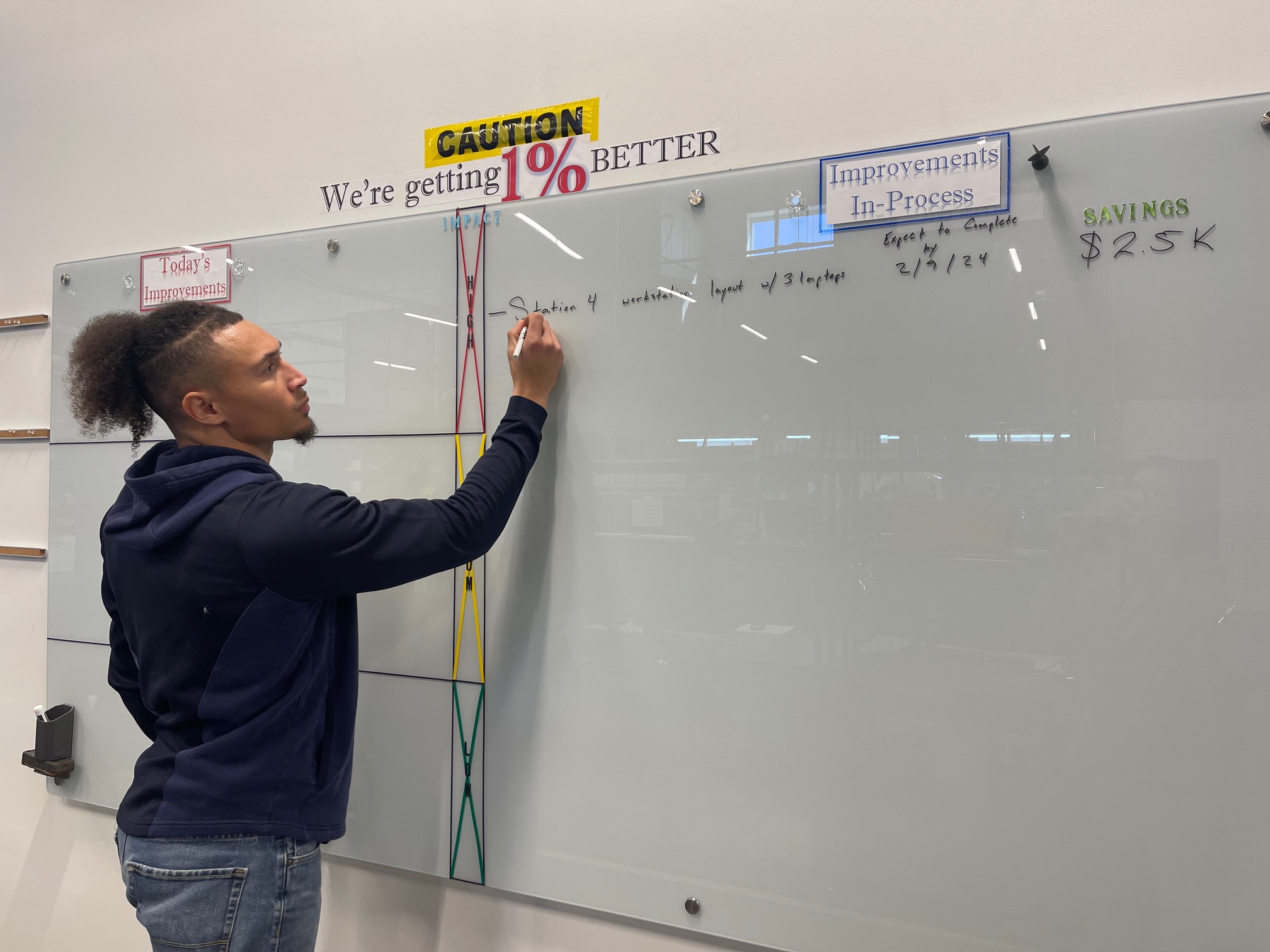

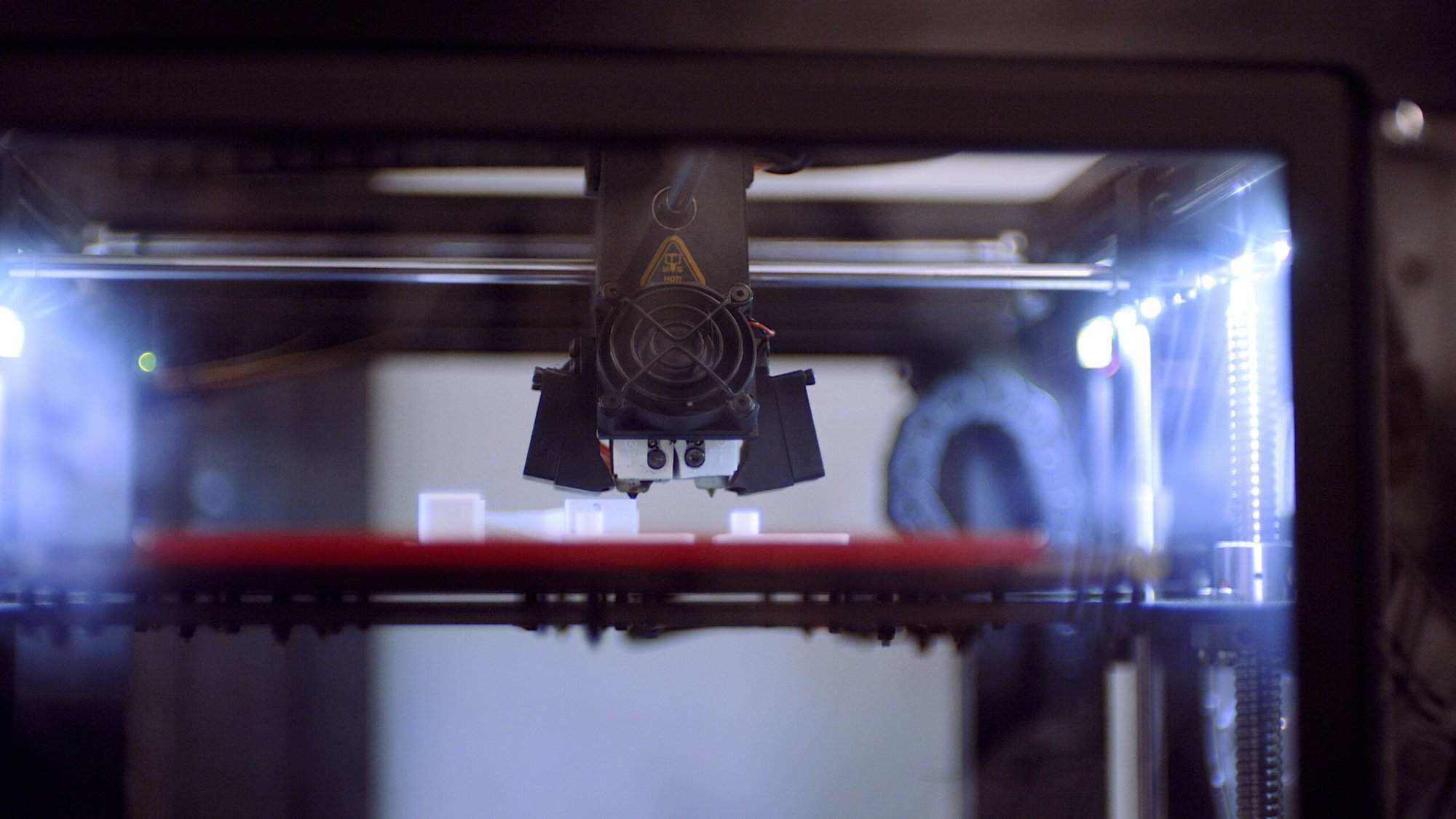

We know that when you don’t innovate, you die. Sometimes it happens quickly, but often it happens slowly. We are motived to have an on-going, vibrant company and believe strongly in continuous improvement. Another of our core values says that we are “averse to the status quo.” Every day we look to improve our products and processes while helping our customers do the same. Throughout our 17 years as a company, we have refused to back down from the variety of challenges that have been presented. We have competed with industry giants, but with tenacious, creative, and innovative employees, we continue to transform every aspect of our organization.

No matter what you’re looking for out of a design or manufacturing partner, E4D Technologies is here to help you move forward. Our innovative approach to medical device manufacturing and regulatory experience has allowed our technology to be sold globally. We would like to offer that same opportunity for your product. Want to learn more about all of the ways E4D can help your company thrive? Check out our offerings today!

And if you want to work at a company with an organizational culture that makes coming to work every day less of a chore and more of a motivating factor, reach out to us today to see what opportunities might be available.

Photo Sourced from E4D Technologies