When you use some form of pull systems, you are not making a product (or sub-assemblies) until you have demand. This means that you can rotate your labor to work on products where you have customer orders and can expect to bill quickly.

Continue readingHow E4D’s Company Culture Contributes to Our Success in Design and Product Manufacturing

At E4D Technologies, we know that a company with a healthy organizational culture will outperform a company with an unhealthy culture. Many companies are smart, but many struggle with delivering timely results with minimal interpersonal drama and disorganization. Patrick Lencioni defines a healthy organization as one that “has minimal politics and confusion, a high degree of morale and productivity and a very low turnover among good employees” (The Advantage, Pg 5). Our smart and healthy organization has successfully competed with much larger organizations and withstood the test. While many of those larger organizations have a brilliant and skilled workforce, we have the advantage of having the strength of a healthy organization to complement our smaller but equally skilled team. As a company that has focused on organizational health and creating a culture where people want to come and work, more than two-thirds of our team has been with us for more than five years; and half of that has been around for more than ten years.

Our culture enables us to innovate technology every day while genuinely enjoying the work that we do and the people who work with us. It helps us succeed in creative development, problem-solving and a variety of essential components of our business. We know every company has a culture, but not all companies intentionally develop a culture that promotes their purpose and values while looking to bring their customers the best value.

Here’s how our company culture contributes to our success in contract design and product manufacturing:

We Like to Say E4D Means Employees 4 a Difference

We understand that progress in the technology industry encompasses more than producing a great product. Not only does E4D make a difference for our customers around the globe with innovative products, but we also bring value to our local communities. We want our company values and ideas to go beyond the walls at E4D Technologies and positively affect people outside of our organization. For example, we make a difference in our community of Richardson, Texas, by uniting our employees in our company-wide volunteer program. We are blessed to be part of a great community that is a vital part of our employees’ lives.

We exist to enable individuals, teams, and companies to have the freedom to move forward. Our team places a heavy emphasis on creating opportunities for our employees to help our neighbors achieve their freedom to move forward. Serving our communities also has the added benefit of building stronger, long-lasting relationships with our employees, which are strengthened as we work to serve the community together.

Leaving Our Egos at the Door

As the cliche goes, “cash is king.” But the reason to be in business is to use that cash to create value. Our team strives to create an environment for the benefit of our customers, employees, end-users, investors, and communities based on mutual improvement, growth, and overall service. Contrary to most beliefs about business, profit is not our only purpose but a direct result of our aim.

One of our core values is that we “leave our egos at the door.” This means that we acknowledge that it takes the whole team, regardless of title or role, to bring the best value to our customers and our employees. We value the diversity of experience, education and culture of our team. We recognize that we all have something important to contribute to each other, to our customers and to our community. Together, our team of experts has nearly 600 years of combined experience in all major engineering disciplines, and our team represents more than ten different countries. Under one roof, we work together to make complex technologies simple and bring our customers’ products to life. Through leveraging our diverse skills, cultures and experience, we provide everyone with the freedom to move forward.

This mindset and value breaks down silos and politics that can impact an organization’s health and deter the company from moving efficiently and effectively to what brings the most value. Our company culture brings our entire staff together with one motivating goal of moving forward. We want to make a difference in the future of design and manufacturing, and we’re working towards this goal every day.

Aversion to the Status Quo

We know that when you don’t innovate, you die. Sometimes it happens quickly, but often it happens slowly. We are motived to have an on-going, vibrant company and believe strongly in continuous improvement. Another of our core values says that we are “averse to the status quo.” Every day we look to improve our products and processes while helping our customers do the same. Throughout our 17 years as a company, we have refused to back down from the variety of challenges that have been presented. We have competed with industry giants, but with tenacious, creative, and innovative employees, we continue to transform every aspect of our organization.

No matter what you’re looking for out of a design or manufacturing partner, E4D Technologies is here to help you move forward. Our innovative approach to medical device manufacturing and regulatory experience has allowed our technology to be sold globally. We would like to offer that same opportunity for your product. Want to learn more about all of the ways E4D can help your company thrive? Check out our offerings today!

And if you want to work at a company with an organizational culture that makes coming to work every day less of a chore and more of a motivating factor, reach out to us today to see what opportunities might be available.

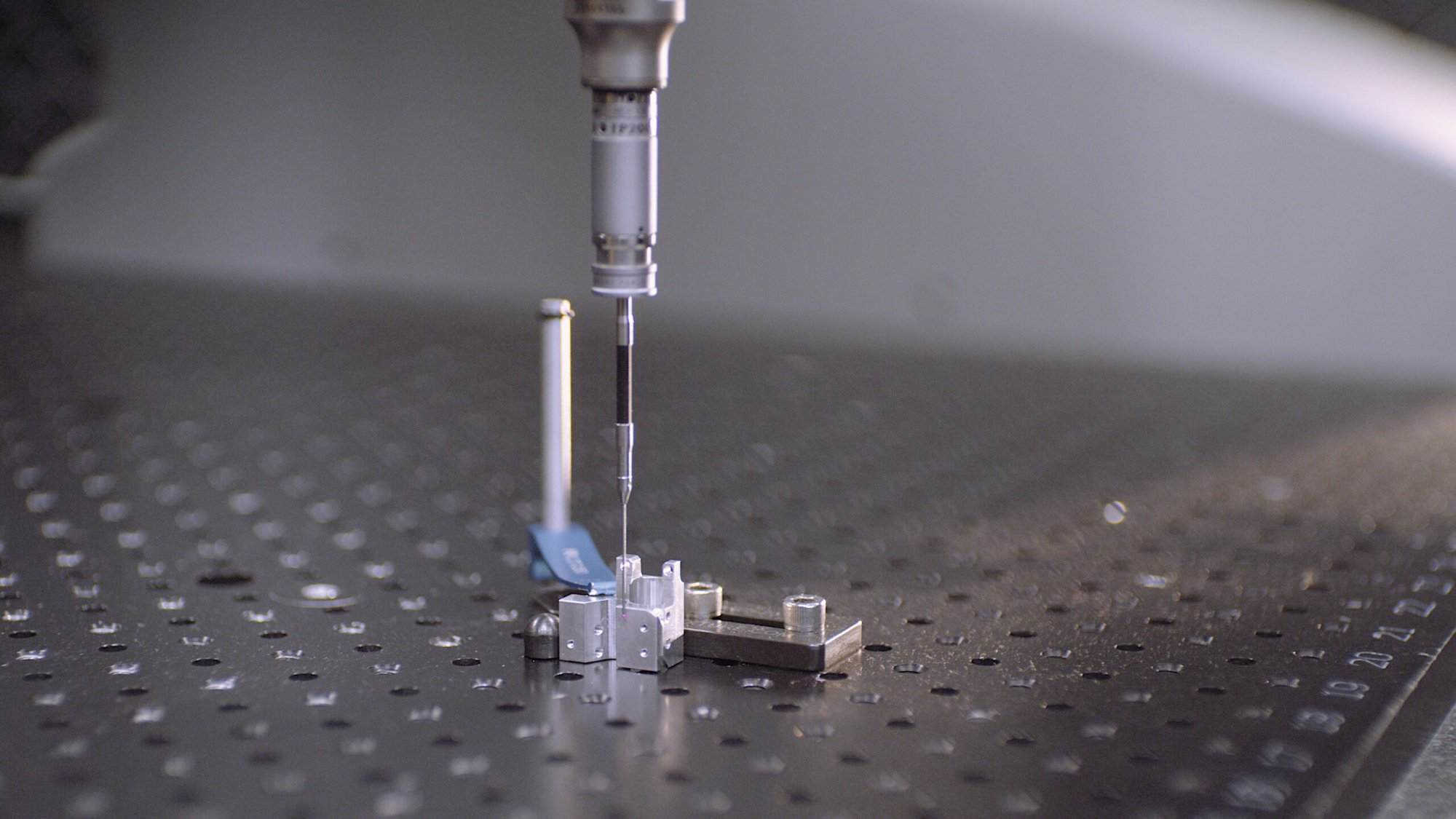

Photo Sourced from E4D Technologies

Fireside Chat with E4D Technologies: How the Pandemic Has Impacted Global Supply Chains

Many people are worried about the COVID-19 impact on technology and the global supply chain. Will the global supply chain have to shrink in order to get stronger? Can we expect to see a change in technology logistics and the global economy coming out of Coronavirus regulations? We sat down with Tammi Carter and Brett Hetherington to provide our industry with insight, personal experience, and analysis of the logistics in technology after the dust settles with COVID-19. Here’s a fireside chat with E4D Technologies about the supply chain:

What Are the Flaws the Pandemic Exposed in The Global Supply Chain?

“Countries around the world addressed the pandemic in different ways. While some countries remained relatively open, others suspended production until they could safely address how to keep their employees safe. How were people going to work at their job without exposing themselves or others to COVID-19? In some cases, governments responded by placing tight restrictions on workers and even forced some manufacturers and suppliers to close their doors for an undetermined amount of time. Regretfully for some companies, this was too big of an impact and they have closed their doors for good. – Tammi Carter

“Coming out of the pandemic, many companies have had to face the harsh reality of relying too heavily on a sole source supplier. Those companies who had already reviewed their supply chain and eliminated much if not all of the sole source components, the impact of COVID was significantly less harmful.

Another element that protected companies was their scalability. As competition increased, and pressure for the existing and remaining suppliers increased in areas of COVID support. Without having the proper infrastructure for documentation, procedure, and training, companies who could still function within government regulations still faced the challenge of being understaffed and ill-prepared to train the number of workers needed.” – Brett Hetherington

What Have Companies Learned about Being Flexible and Agile?

“As people began to rush to stores to pick-up essentials, the global economy was in a crisis to continue to supply consumers with goods and services. Many businesses realized the importance of infrastructure and logistics in order to keep their customers happy while managing to stay operational. Properly scaling a business up became a necessity, but also effectively scaling a business down was equally crucial in specific industries. With a lack of supply and demand, how can you manage to stay operational? Companies not only had to find a way to cut costs, but they also needed new sources of income. One of the biggest challenges in many business structures and systems was the lack of training, documentation, testing, and discipline in their field. While some companies could handle the drastic change, others went out of business because they couldn’t ramp up or ramp down production due to a lack of organization.” – Brett Hetherington

“The supply chain also faced a challenge with logistics. Not only from the standpoint of having a sole supplier but also from the perspective of audits and inspections. How could you continue to perform the standard supplier audits when global travel was largely banned? Companies that had strong suppliers and a strong existing quality system found transferring to a virtual audit and review relatively simple. However, if none of that infrastructure existed, then it became a real test of trust between the client and the supplier. In some cases, to add additional suppliers or to eliminate the need for global travel, some companies have considered adding additional domestic suppliers..” – Tammi Carter

How Will the Supply Chain Look Coming Out of the Pandemic?

“There is no doubt that there will be fewer players in almost every industry. In [our] opinion, there won’t be drastic changes to how the global supply chain functioned before the pandemic. Ultimately, the world is too interconnected. It would be difficult to quickly change how it operated for decades before this point. We will see companies doing a thorough analysis of the supply chain and look for opportunities to dual-source and, as much as possible, source domestically. ” – Tammi Carter

“We do think that companies like E4D who are not able to do the majority of the work at home, will adapt lessons learned from this pandemic as it relates to keeping employees healthy at work. We would anticipate physical layouts of factories to take social distancing into consideration where possible. Wearing masks and some safety procedures will likely stay to protect workers from team members exhibiting cold or flu symptoms. More than likely, people will continue to wear masks when feeling ill, cleaning habits will stay in place, and we may even see an impact on factories’ design and layout.” – Brett Hetherington

What Will E4D Look Like After the Pandemic?

“As an essential business, E4D was open to support our healthcare professionals. We definitely experienced a slow down in some market segments while others grew exponentially. We attribute our abilities to our reliance on our strong quality systems and our flexible and creative team. We were able to function because we successfully ramped up our systems while simultaneously scaling down other areas of our business. Our documentation, training, procedures, testing, and discipline allowed us to keep our team on the manufacturing floor while supplying our customers with their orders. Some aspects of our company had to change, and with every change, we were transparent and honest with our team to make sure everyone was on the same page. E4D Technologies is more experienced, knowledgeable and agile than ever before. We couldn’t have done it without our fantastic team, and we’re so grateful to still be here today. Our process, development and company culture kept us moving forward even during the difficult moments.” – Tammi Carter

Ready to partner with E4D for manufacturing or design? Our advanced experience in technology design, manufacturing technology and logistics in technology can help your business achieve all of your goals. All aspects of our company work under one roof so that you can access all of our unique technological disciplines. If you’re ready to hear what we can offer your business, we want you to contact us today.

Photo Sourced from E4D Technologies

Understanding Medical Device Regulation Needs and How We Help You Bring A Product to Market

Navigating medical device regulations and obtaining product approvals on your own is a daunting and challenging task. Understanding and applying medical device regulations effectively can make or break a company for any new technology. At E4D Technologies, we have the industry knowledge and expertise to help you understand the requirements of global medical device regulations and how to bring your product to market as soon as possible. Here are some ways E4D can help you:

Understanding Medical Device Regulation by Country

Every country has its own set of rules when it comes to a new product introduction. Medical devices are regulated by the FDA in the United States, by Health Canada (HC) in Canada, the NMPA in China and, the European Commission (EC) in the EU. With many countries having their own set of rules, licensing requirements and labeling regulations, this can cause a whirlwind of confusion for any company trying to manufacture medical devices. Through our experience, we’ve learned that meeting all the requirements for one organization’s set of rules doesn’t always mean that you’ll be able to get clearance in other countries. China always requires in-country testing regardless of approval from other countries. In Europe, the regulatory process is quite different than that of the US.

Not all medical devices are regulated equally. Since medical devices will use different technology and materials, and will have different indications for use, the risk of each category of device is treated differently. For instance, a medical device implanted in a person’s heart will have to undergo rigorous testing. The company will have to report in great detail about any life-threatening occurrences that may happen as well as serious, minor or if no injuries have occurred. These high-risk devices have to complete long and detailed clinical trials and often take several years before they can be introduced into the market. Even some PPE products could fall into life-threatening high-risk categories. On the other hand, lower risk devices such as many dental devices and non-invasive devices are able to enter the market much faster.

Assessing Risk and Establishing Benefits through Research

Every government medical device regulation can be connected to keeping patients safe and to the device’s effectiveness while clearly defining the risks. Medical device product development requires risk assessment and extensive research and testing of the product. The main questions government regulatory entities will ask are, “does it do what you claim it will do?”, “is it safe and effective for your claimed indications for use?” and “is it substantially equivalent to your claimed predicate device?” Taken directly from the FDA, “The legally marketed device(s) to which equivalence is drawn is known as the predicate device(s).” While your product is going through the development life cycle, you and your team will need to ask yourself:

● Does the device do what it claims to do?

● What is the risk of this product failing?

● What are the failure points?

● What happens if the product fails? Will failure create serious or life-threatening risks?

● How can we prevent the device from failing in high-risk situations?

● Do the benefits of using the device outweigh any residual risks?

Developing a medical device can take a lot longer than anticipated. The leading cause for companies failing to bring a medical device to market is usually connected to establishing substantial equivalence to the chosen predicate device. The key in this stage is to have a comprehensive timeline with attainable goals and room for error. Many unforeseen obstacles can appear during the development phase, and we always advise our clients to plan for the unknown.

Testing, Manufacturing and Bringing It to Market with E4D

Bringing your new medical device to market is extremely difficult on your own. Meeting with experts in the industry who have established experience is one of the best ways to bring your medical device to market. One route you may consider going down is hiring an independent medical technology consultant. This may require a significant amount of funding, time and resources because most consultants are expensive. Without having to bust the bank or causing you to take two steps back with your new technology, we would eagerly lend you a helping hand.

At E4D Technologies, we have a dedicated team of experienced technology consulting experts, technology logistics personnel and global supply chain leaders. We have worked with companies to help bring their new product to market, and we’ve helped them navigate through a broad range of medical device regulations. Our team can help you with development, usability, testing, risk assessment, regulatory/compliance submissions and manufacturing, all under the same roof. You need someone who can ask the right questions, give you the correct answers, guide you through any process and be realistic with you every step of the way. Our experienced team knows how important your business is to you, and we want to help you succeed.

Whether you are looking for a new manufacturing partner or you need an experienced team to help you navigate medical device regulation requirements, the team at E4D Technologies wants to hear from you. With unique experience and specialties covering all major technology and manufacturing disciplines, we’re confident that you’ll find exactly what you’re looking for through E4D Technologies. Understanding and meeting regulations and requirements for new technology and existing technology doesn’t have to be overwhelming, and we’re waiting to hear from you today.

Want to learn more about what E4D Technologies has to offer your business? Contact our team to find out how we can help and meet your specific needs.

Photo Sourced from E4D Technologies

The Significance of the Six Sigma Black Belt with E4D Technologies

At E4D Technologies, we work hard to deliver exceptional quality in everything we do. One of our core values is that we are “Averse to the Status Quo”. This drives us on a continuous improvement journey throughout the whole organization. Two of the tools in our continuous improvement toolbox are: Six Sigma and Lean manufacturing. Here are the reasons why Six Sigma and Lean manufacturing are so significant to our processes at E4D:

What Is a Six Sigma Black Belt Certification?

The Six Sigma Black Belt Certification is one of the most comprehensive certifications in our industry. Any person who can rise to the challenge to complete this certification is certified in the Six Sigma philosophies and principles, and they’re a master of using the DMAIC process to reduce variability while leading and supporting the Six Sigma team. We have one Certified Black Belt on our team, but the principles of Six Sigma are taught to our entire engineering team. These principles keep us focused on continuously improving the reliability and quality of our products and processes.

What is the Significance of Lean Manufacturing?

Lean Manufacturing is similar to the principles of Six Sigma in some ways, but completely dissimilar in others. The concept of lean manufacturing is based on eliminating waste while maximizing customer value. In following the guidelines of Lean Manufacturing, we look at the 8 wastes and continually look for ways to add value and eliminate waste.

The Differences Between Six Sigma and Lean Manufacturing

As a leader in advanced technology used for manufacturing, we believe that every great system serves an important role in the workplace. Lean Manufacturing and Six Sigma may sound similar at first, but the differences are important to understand. Lean manufacturing is a process for reducing waste in the workplace, while Six Sigma works to reduce variations. Both present tools that help make the design and manufacturing process more effective.

We are huge proponents of both Lean Manufacturing and Six Sigma. We work hard to deliver a manufacturing experience that puts our clients, and their products, first. To find out more about how we can help manufacture your products with future technology innovations and processes, contact our team today.

Header Photo Sourced from E4D Technologies