In a world where efficiency and innovation are paramount, E4D Technologies works tirelessly to push forward, especially through the continuous improvement methodologies like Lean Six Sigma. Dominique Ramsey, an aspiring continuous improvement lead at E4D Technologies, shared his journey and insights into Lean Six Sigma Black Belt training, a path that not only enhances personal growth but also drives organizational excellence.

Unlocking Potential with Lean Six Sigma

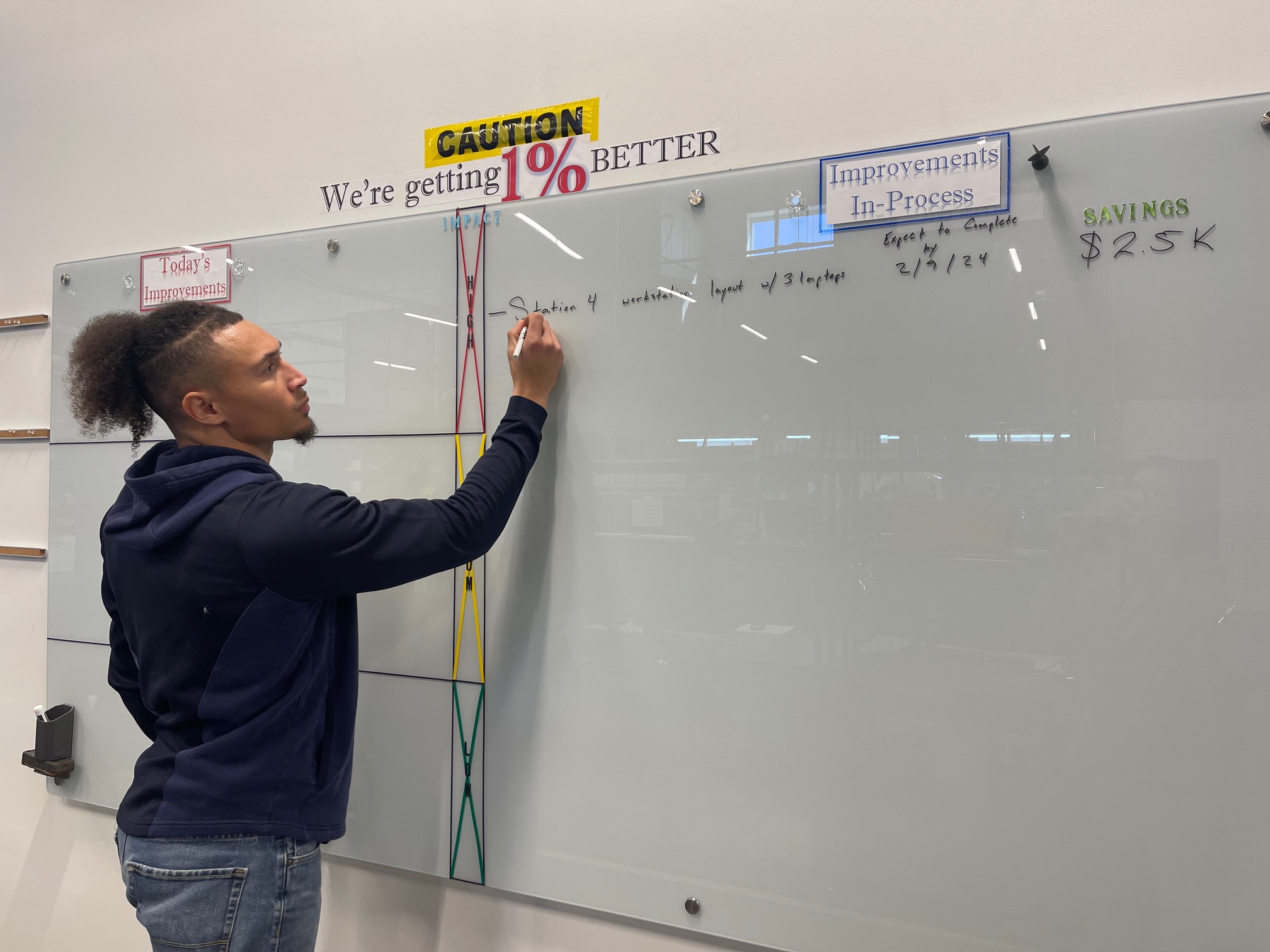

Dominique’s venture into Lean Six Sigma is fueled by a deep-rooted belief in constant improvement and a 1% daily growth mindset. Lean Six Sigma’s principles mirror the patterns of daily life, where even the simplest routines can be optimized for significant impact. This approach resonates with E4D’s commitment to excellence – where small, consistent improvements lead to groundbreaking innovations.

Challenges and Triumphs in Six Sigma Black Belt Training

The journey through Lean Six Sigma is not without its challenges. For Dominique, selecting the right project that adds value to E4D’s core mission was crucial. His focus on E4D’s primary medical device, the OEM scanner projects, despite his primary role in contract manufacturing lines, exemplifies his commitment to adding value and enhancing efficiency. This aligns perfectly with E4D’s vision of delivering exceptional quality, innovation in their products and aversion to the status quo.

Practical Application: Transforming Theory into Action

Dominique’s training in DMAIC (Define, Measure, Analyze, Improve, Control) principles and his emphasis on statistical data over opinion, highlights the shift towards a more empirical approach in problem-solving. Applying these principles in daily tasks, much like his experience in college football, shows how continuous improvement is integral to both personal and professional growth. This approach is crucial in E4D’s mission to constantly evolve and provide superior solutions.

In conclusion, Dominique Ramsey’s journey in Lean Six Sigma Black Belt training is not just a personal achievement, but a testament to E4D Technologies’ commitment to fostering a culture of continuous improvement and excellence. Dominique’s new skills and mindset will undoubtedly contribute to the innovative and high-quality products and services that E4D offers to its clients. Want to learn more about Lean Six Sigma and its impact on technology and innovation? Contact our team today to take your next step forward.

Photo Sourced from E4D Technologies